Why it's important to us that you check the anchor base-plate rigidity

Modern fixtures allow structures to transfer heavy loads, and these safety-relevant joints must be designed with precision. A widespread and consolidated approach when it comes to calculating a steel-to-concrete connection assumes that the anchor base-plate remains flat and elastic under the influence of forces. Most likely, this is what you considered in all your previous post-installed anchor designs. As is the case with any other assumptions, this must be confirmed.

This post is inspired by a comprehensive technical dissertation on this subject published in Stahlbau (you can find the link to the reprint translation of the original German report at the very end of this page):

What does rigid anchor base-plate mean?

In theoretical rigid anchor base-plate behavior, the load distribution is simplified by assuming that the plate itself does not deform analogously to Euler-Bernoulli’s beam theory. Strains are distributed linearly through the cross-section of the anchor base-plate.

Under this hypothesis, the load distribution under the plate and the anchor are determined as illustrated in the next figure.

Reaction forces in the fixture due to a bending moment,

tension and compression load in a rigid anchor base-plate

This simplified beam theory is well accepted by civil engineers, mainly because it can prove that the cross-section does not deform for beam elements with small cross-section dimensions in relation to the longitudinal extension. This is not always the case for a steel anchor base-plate, where the longitudinal dimension is represented by the plate thickness.

Let’s further outline the problem by looking at the three main consequences of incorrectly applying the rigid theory for an insufficiently stiff anchor base-plate.

Consequence 1: Higher loads on anchors and higher stress on concrete

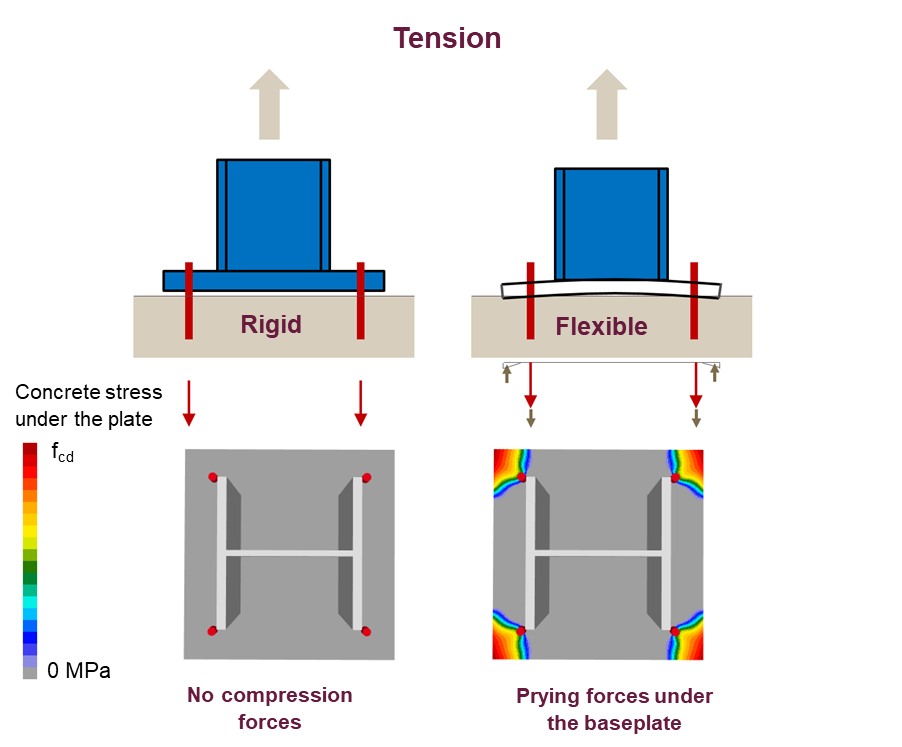

If, in contrast with the assumption, a flexible anchor base-plate is used, this may lead to a reduction in the lever arm of the internal forces and thus to higher loads on the fixture, depending on the rigidity. The plate corners can become compressed against the concrete, inducing additional prying forces which, in turn, lead to an increase in the tensile force in the anchors.

The reduction of the level arm in a flexible anchor base-plate

results in higher tension load in the anchors and prying force on the concrete

These prying forces can also occur with larger anchor base-plate protrusions, flexible anchor base-plates and predominantly tensile loads, where the deformation of the loaded anchor base-plate leads to significant overloading and premature failure of an anchor within a group.

In a tensioned flexible or rigid base-plate anchor base-plate,

the prying forces are equilibrated by higher tension load in the anchors

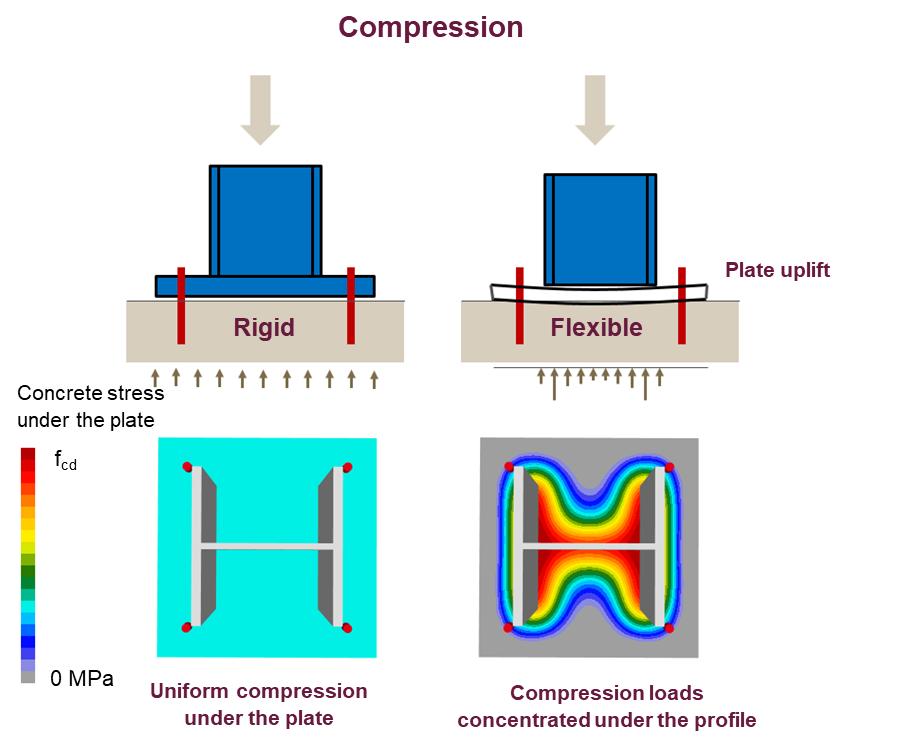

Also, in the case of a non-stiff plate under predominantly compression load, the stress distribution on the concrete under the plate might result in higher values than those calculated where rigid anchor base-plate behavior design is assumed.

In a compressed flexible or rigid anchor base-plate,

the stress distribution results in higher concentrated loads on the concrete base

Consequence 2: Non-compliance with anchor design codes

In most international standards such as Eurocodes 2 and ACI 318, resistance equations for a group of anchors are based on rigid anchor base-plate assumptions only. Therefore, by using the formulas provided by these guidelines in the case of flexible anchor base-plates, the anchor calculation can lead to inaccurate results. This is why the disclaimer for checking the rigidity of the plate is clearly stated in the anchor calculation report with the PROFIS Anchor software.

Consequence 3: Underestimated deflection in SLS

Non-rigid anchor base-plates tend to exhibit greater deformation than rigid plates. For a cantilever beam, a non-rigid anchor base-plate will result in greater displacement as there is more rotation in the anchor base-plate. As an engineer, you should consider this in the SLS assessment, especially in cantilever and self-standing applications.

Displacement of the cantilever beam in the case of rigid and non-rigid anchor base-plates

The solution

It should now be clear that assessing the plate rigidity is critical in terms of application safety. Despite this, no clear rules are available in literature on how to properly validate this requirement. Therefore, this step is generally omitted or qualitative judgement on the plate geometry (e.g. ‘thick-enough feeling’) and stiffeners arrangement are only considered.

It's quite simple, FEM analysis is the state of the art for a realistic assessment of anchor base-plate rigidity and for ensuring an adequate design of the full connection.

With the Hilti PROFIS Engineering Suite it will be possible to calculate plates taking into account flexibility and the real behavior of plate module components. It provides a precise verification of all the components of a joint, combining the component method commonly used in steel construction with a powerful CBFEM (Component Based Finite Element Method) finite element calculation.

Share your thoughts or questions, or request of information about the brand-new upcoming PROFIS Engineering software, by leaving a comment.

You can also request a seminar/ demo in your office by clicking here.